S220GD+Z Galvanized Steel Plate

Product Name : S220GD+Z Galvanized Steel Plate

Thickness : 0.12mm-6.00mm or As your request

Width : 600mm-1500mm

Length : 1m-12m , Support Customization

Zinc coating : Z40-600g/m2

Standard : GB,JIS,DIN,AISI,ASTM

Low Maintenance, High Performance

Affordable Excellence

Swift Delivery

Professional After-Sales Support

Product Description:

S220GD+Z Galvanized Steel Plate is a low alloy steel grade known for its exceptional strength and corrosion resistance. This product is compliant with the EN 10346-2015 standard, which specifies the technical delivery conditions continuously hot-dip coated steel flat products for cold forming. Characterized by a minimum yield strength of 220 MPa, S220GD+Z offers a robust zinc coating that provides excellent protection against rust and other forms of corrosion, making it suitablefor a variety of applications in construction, automotive, and home appliances. The steel plate is also recognized for its high size precision, flat profile, and good mechanical properties, which include processing and welding.performance. With its versatile use in structural components and reinforcements, S220GD+Z is an ideal choice for industries seeking a balance of strength and durability with resistance to environmental degradation.

Product Manufacturing Process:Chemical degreasing → hot water washing → water washing → electrolytic degreasing → water washing → acid washing → rust removal → water washing → electrogalvanizing process → water washing → passivation → hot water washing → drying → quality inspection → packaging and sales

Chemical Composition

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | - |

| Use of The Environment | Recommended Zinc Thickness |

| Indoor Use | Z40 or Z120 (40g/㎡or 120g/㎡) |

| Suburbs | Z200 and Painting (200g/㎡) |

| Urban or Industrial Area | Z275 (275g/㎡) or G90 (US Standard) and painted |

| Coastal Area | Thicker than Z275 (275g/㎡) or G90 (US Standard) and painted |

| Punch or Deep Drawing Application | Thicker than Z275 (275grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

| Surface Treatment Type | Code | Features |

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

Competitive Pricing: We offer our products at competitive prices without compromising on quality.

Customer Service: Our dedicated team is always ready to assist you with any inquiries or support you may need.

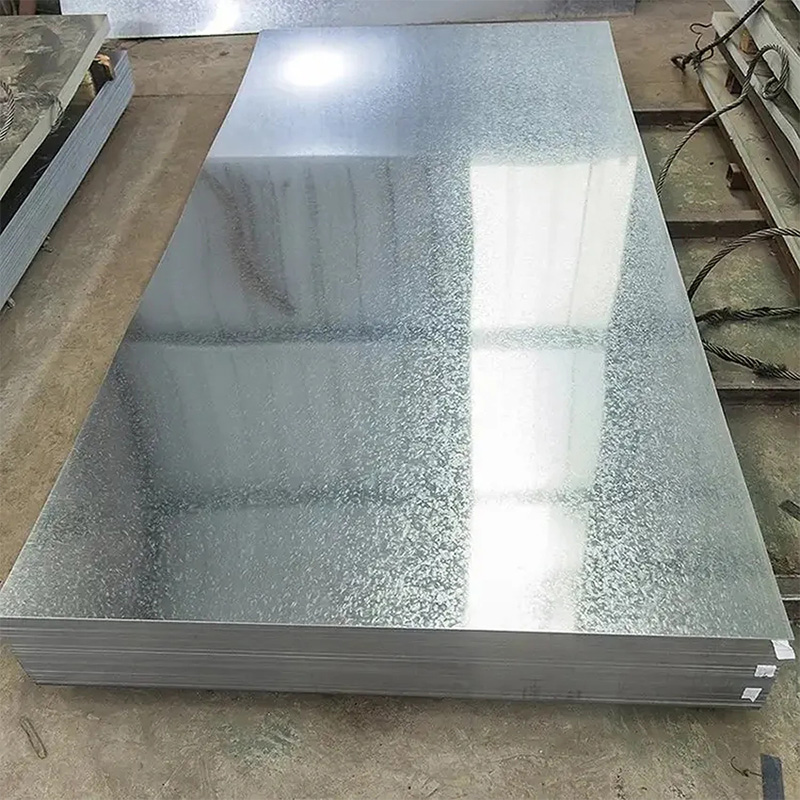

Product Show:

Packaging And Shipping:

Submitted successfully

We will contact you as soon as possible