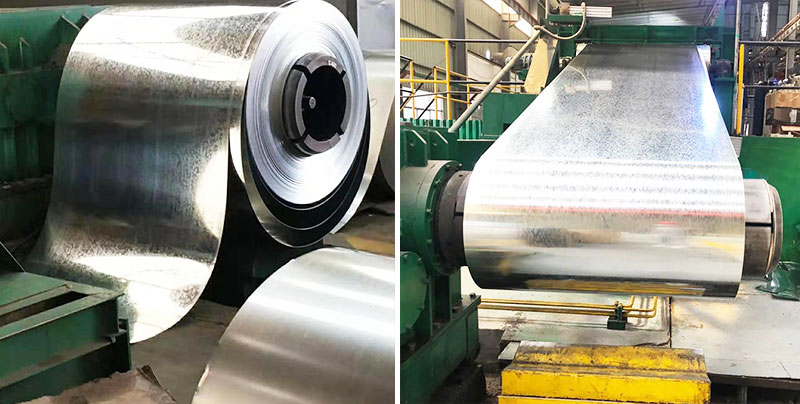

DX51D+Z Galvanized Steel Coils

Product Name :DX51D+Z Galvanized Steel Coils

Thickness :0.12mm-3.5mm

Width : 600mm-1500mm

Zinc Layer: 40-400g/m²

Standard : AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc.

Low Maintenance, High Performance

Affordable Excellence

Swift Delivery

Professional After-Sales Support

Product Description:

In the manufacturing of auto parts, many body structure parts and interior trim parts of different shapes can be processed with DX51D steel, which can be accurately formed in the stamping process, and maintain good surface quality, reduce subsequent dressing procedures, and improve production efficiency.

Full cold galvanizing process:

Chemical degreasing → hot water washing → water washing → electrolytic degreasing → water washing → acid washing → rust removal → water washing → electrogalvanizing process → water washing → passivation → hot water washing → drying → quality inspection → packaging and sales

Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Ti |

| Forcold FormingChinese Standard | DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

| DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| Forcold FormingJapanese Standard | SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

| SGCD1SGCD2 | 0.120.10 | 0.500.50 | 0.600.45 | 0.0400.030 | 0.0300.030 | 0.0250.025 | |

| SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| For StructureJapanese Standard | SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

| SGC400SGC440 | 0.250.25 | 0.500.50 | 1.702.00 | 0.2000.200 | 0.0350.035 | 0.1500.150 | |

| SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

| SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

| For StructureAISI Standard | S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

| S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

| S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | - |

| Use of The Environment | Recommended Zinc Thickness |

| Indoor Use | Z40 or Z120(40g/㎡or 120g/㎡) |

| Suburbs | Z200 and Painting (200g/㎡) |

| Urban or Industrial Area | Z275 (275g/㎡) or G90 (US Standard) and painted |

| Coastal Area | Thicker than Z275 (275g/㎡) or G90 (US Standard) and painted |

| Punch or Deep Drawing Application | Thicker than Z275 (275 grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

| Surface Treatment Type | Code | Features |

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

| Chinese Standard | Japan Standard | European Standard |

| DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

| DX52D Z/DC52D Z | SGCD1 | DX52D With |

| DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

| S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

| DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |

Competitive Pricing: We offer our products at competitive prices without compromising on quality.

Customer Service: Our dedicated team is always ready to assist you with any inquiries or support you may need.

Production And Shipping: