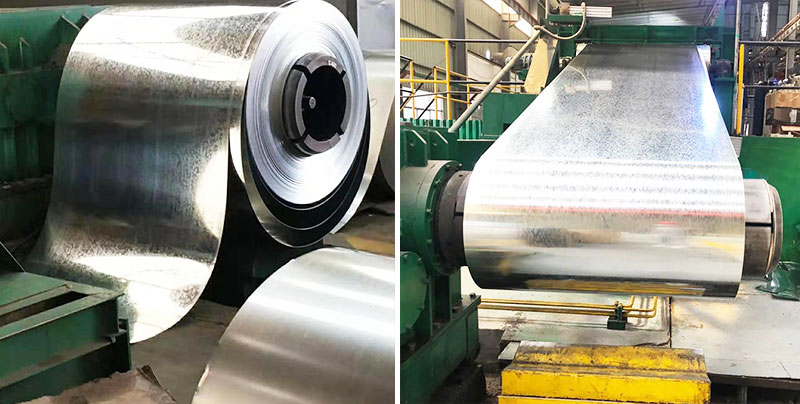

4mm Galvanized Steel Coils

Product Name :4mm Galvanized Steel Coils

Thickness :0.1mm-5mm

Width : 500mm-1500mm

Zinc Layer: 40-400g/m²

Standard : AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc.

Low Maintenance, High Performance

Affordable Excellence

Swift Delivery

Professional After-Sales Support

Product Description:

Our 4mm Galvanized Steel Coils are a testament to unrivaled craftsmanship and state - of - the - art technology. The super - thick, premium - grade zinc coating offers unmatchable corrosion resistance, positioning them as the definitive choice for the most severe and challenging environments.

These coils are engineered for colossal infrastructure undertakings such as large - scale offshore platforms, massive industrial processing plants, and extra - large - scale mining facilities. They are also perfect for manufacturing heavy - duty construction equipment like large - capacity cranes, and super - thick - walled storage tanks for hazardous materials. The 4mm thickness confers unparalleled strength and unbeatable rigidity, allowing them to withstand extreme stress, intense hydraulic pressure, and the most substantial dynamic impacts. Despite this substantial thickness, the coils retain remarkable formability, enabling them to be shaped into highly intricate and precise components.

Under stringent, comprehensive quality control, these coils ensure consistent, long - lasting, and reliable performance. They are a cost - efficient solution for those in pursuit of top - notch, ultra - strong, and extremely durable metal materials, providing excellent value for money across diverse high - stress applications.

Full cold galvanizing process:

Chemical degreasing → hot water washing → water washing → electrolytic degreasing → water washing → acid washing → rust removal → water washing → electrogalvanizing process → water washing → passivation → hot water washing → drying → quality inspection → packaging and sales

Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Ti |

| Forcold FormingChinese Standard | DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

| DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| Forcold FormingJapanese Standard | SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

| SGCD1SGCD2 | 0.120.10 | 0.500.50 | 0.600.45 | 0.0400.030 | 0.0300.030 | 0.0250.025 | |

| SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| For StructureJapanese Standard | SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

| SGC400SGC440 | 0.250.25 | 0.500.50 | 1.702.00 | 0.2000.200 | 0.0350.035 | 0.1500.150 | |

| SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

| SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

| For StructureAISI Standard | S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

| S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

| S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | - |

| Use of The Environment | Recommended Zinc Thickness |

| Indoor Use | Z40 or Z120(40g/㎡or 120g/㎡) |

| Suburbs | Z200 and Painting (200g/㎡) |

| Urban or Industrial Area | Z275 (275g/㎡) or G90 (US Standard) and painted |

| Coastal Area | Thicker than Z275 (275g/㎡) or G90 (US Standard) and painted |

| Punch or Deep Drawing Application | Thicker than Z275 (275 grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

| Surface Treatment Type | Code | Features |

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

| Chinese Standard | Japan Standard | European Standard |

| DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

| DX52D Z/DC52D Z | SGCD1 | DX52D With |

| DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

| S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

| DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |

Competitive Pricing: We offer our products at competitive prices without compromising on quality.

Customer Service: Our dedicated team is always ready to assist you with any inquiries or support you may need.

Production And Shipping: