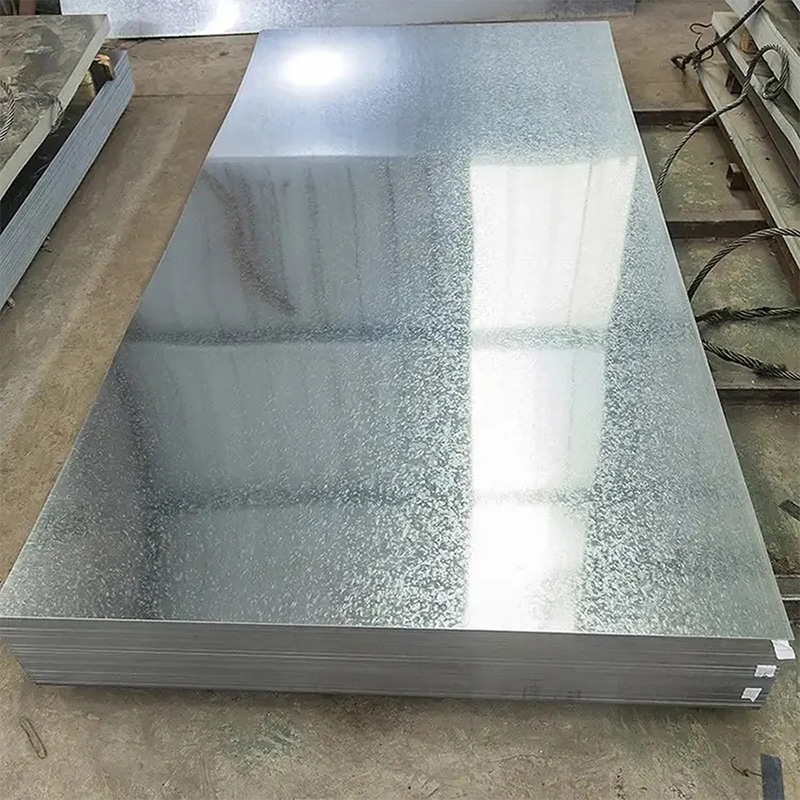

Introduction to Galvanized Sheet

galvanized steel sheet is a high-quality building material widely used in industry and construction fields. By coating a layer of anti-corrosion zinc on the surface of the steel plate, Galvanized steel plates have excellent advantages over ordinary steel plates.

galvanized steel plate is a welded steel plate with a hot-dip or electroplated zinc layer on the surface. It is generally widely used in construction, home appliances, vehicles and ships, container manufacturing, mechanical and electrical industries, etc.

Classification of galvanized steel sheets

It can be divided into the following categories according to production and processing methods:

①Hot-dip galvanized steel plate.

②Alloyed Galvanized steel sheet.

③Electro-galvanized steel plate.

④ Single-sided galvanized steel plate and double-sided galvanized steel plate.

⑤Alloy, composite galvanized steel plate.

In addition to the above five types, there are also colored galvanized steel sheets, printed and painted galvanized steel sheets, PVC laminated galvanized steel sheets, etc. But the most commonly used is still hot-dip galvanized sheet.

Exterior

(1) Surface condition: Due to different treatment methods in the coating process, the surface conditions of galvanized sheets are also different, such as ordinary zinc flowers, fine zinc flowers, flat zinc flowers, no zinc flowers, and phosphated surfaces. German standards also specify surface grades.

(2) The galvanized sheet should have good appearance and should not have defects that are harmful to the use of the product, such as no plating, holes, cracks and scum, excessive plating thickness, scratches, chromic acid dirt, white rust, etc.

Package

It is divided into two types: galvanized sheet cut into fixed lengths and galvanized sheet packaging in coils. It is generally packed in iron sheets, lined with moisture-proof paper, and tied to a bracket with an iron waist. The bundling should be secure to prevent the galvanized sheets inside from rubbing against each other.