Color coil market heat rise, advanced production technology to help industrial development

Recently, the color roll market has shown a booming trend, and its demand is growing in many areas, which is inseparable from its continuous improvement of production technology.

Substrate preparation: The substrate of the color coated coil is usually cold-rolled strip steel or hot-rolled strip steel, and some will also use hot galvanized sheet, hot aluminum plated zinc plate, electrogalvanized sheet, etc. First of all, these raw materials are flattened, cut, finishing and other pretreatment processes to make sheets that meet the production requirements, and can be customized according to customer needs and thickness 135.

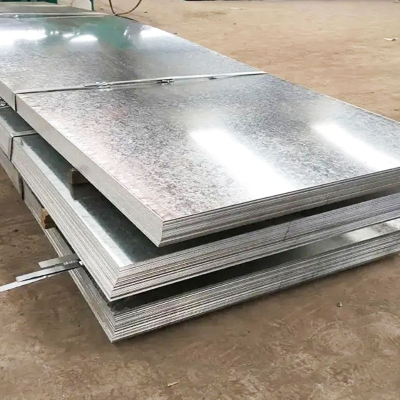

Surface treatment: In order to enhance the corrosion resistance and beauty of the color coated coil, the surface treatment of the molded coil is required. The common methods are hot dip galvanizing and electric galvanizing, hot dip galvanizing is the steel plate soaked in hot zinc solution, so that its surface to form a layer of zinc coating; Electrogalvanizing uses an electric current to attach the zinc coating to the surface of the steel plate. In addition, there are chemical degreasing and chemical conversion treatments to ensure good adhesion of the subsequent paint film 135.

Coating: After the surface treatment is completed, the surface of the coil should be cleaned to remove oil and rust, and then the primer spray and top paint spray. The primer mainly plays the role of anti-corrosion and enhance adhesion, and the top paint is used to increase the color and decorative effect. The choice of coatings will be based on the use of the environment and customer requirements, such as polyester coating is usually used in general building materials and home appliance manufacturing, providing good weather resistance and decorative; Silicon-modified polyester has good weather resistance and heat resistance and is suitable for harsh environmental conditions. Fluorocarbon coatings have excellent weather resistance, chemical resistance and wear resistance, and are often used in high-end construction and automotive manufacturing.

Baking curing: After coating, it is necessary to bake curing in a high-temperature baking room to make the coating dry and firmly attached to the surface of the steel plate. The baking time and temperature are precisely adjusted according to the type of coating and process requirements to ensure the best performance and quality of the coating.

Processing and shaping: After coating and baking curing, the steel coil needs to be processed into the required coil or sheet through calendering, cutting and other processes to meet the size and shape requirements of different application scenarios.

Technological innovation and development

In recent years, color coating coil manufacturers have continuously innovated in process technology, which has promoted the improvement of product performance and the expansion of market. For example, the research and development of new coatings has achieved remarkable results, and some coatings with special functions such as self-cleaning, antibacterial, and heat insulation have been applied to the production of color coating rolls, so that it not only has traditional protective and decorative functions, but also can meet the needs of more specific scenes, such as the use of self-cleaning color coating rolls in places with high environmental protection requirements, which can effectively reduce maintenance costs.

At the same time, the production equipment is also constantly upgraded, and the advanced automated production line can more accurately control the thickness and uniformity of the coating, reducing the impact of human factors on product quality, improving production efficiency and reducing production costs. In terms of quality control, with the help of advanced testing technology and equipment, the paint thickness, surface smoothness, hardness, corrosion resistance and appearance color of color rolls are strictly tested to ensure that each batch of products meet high standards of quality requirems.15

In short, the continuous progress of color coating production technology has provided strong support for its wide application in many fields such as construction, home appliances, automobiles, and so on, and has also injected a strong impetus for the sustainable development of the industry. With the further innovation of technology and the continuous growth of market demand, color coating is expected to create a broader market space and more application value in the future.