Analysis of market dynamics and production technology of galvanized coil

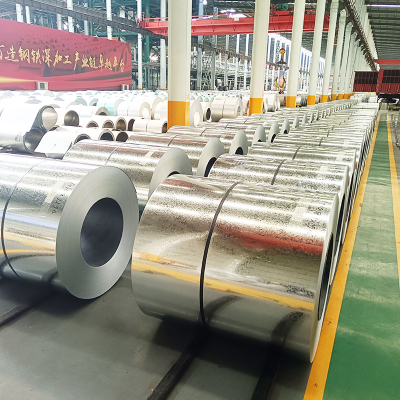

The production process of galvanized coil mainly has two kinds of hot dip galvanizing and electric galvanizing, the following is a detailed introduction:

Hot-dip galvanizing process

Surface pretreatment: First of all, the surface treatment of the steel plate, including cleaning, oil removal and rust removal processes, to ensure that the surface of the steel plate is clean and smooth, to provide a good foundation for subsequent galvanized, enhance the adhesion of the galvanized layer 1.

Pickling and phosphating: pickling is to soak the steel plate in the acid solution to remove the surface oxide and rust; Phosphating is to form a phosphate layer on the surface of the steel plate to further improve its binding force with zinc, so that the galvanized layer is more solid.

Annealing: For rolled hard strip steel, recrystallization annealing is required to obtain good mechanical properties of the product, and by controlling the atmosphere in the furnace, to improve the performance of the strip coating. Annealing furnace is generally composed of preheating, heating, soaking heat, cooling and so on.

Molten galvanizing: The treated steel plate is immersed in a high-temperature zinc solution, so that the liquid zinc forms a uniform zinc layer on the surface of the steel plate. After the zinc pan, gas, such as air or pure nitrogen, can also be blown by the air knife to precisely control the coating thickness on the strip surface.

Alloying treatment: Part of the galvanized coil will be heated immediately after galvanizing, so that zinc and iron will form an alloy coating, forming a zinc-iron alloy coating, which has good coating tightness and weldability.

Post-treatment: including leveling and tension straightening, eliminating the yield platform of low carbon steel by rolling with small rolling force, improving strip properties, and obtaining the desired surface roughness and straightness; And passivation or other chemical surface treatment to meet the user's specific requirements for corrosion resistance, lubrication, etc.

Electrogalvanizing process

Steel coil pretreatment: clean the surface of cold rolled steel coil to remove impurities such as oil and rust spots, and ensure the adhesion and uniformity of the coating.

Electroplating: The pre-treated steel coil is placed in the plating tank, and the zinc layer is uniformly attached to the surface of the steel plate through an electrochemical reaction to form a fine layer of zinc14.

Cold coiling treatment: The steel coil after electroplating is cold coiling treatment and rolled through the cold rolling machine to achieve the specified thickness and flatness 4.

Surface polishing: surface polishing of the cold-rolled electrogalvanized coil, grinding the surface, improve the surface finish and gloss, so that its appearance is more beautiful, suitable for high surface quality requirements of the application scenario4.

These advanced production processes make galvanized coil excellent in corrosion resistance, wear resistance, aesthetics, etc., which has been widely used in many fields such as construction, automobiles, home appliances, electronics and so on, and has promoted the development of related industries. With the continuous progress of technology, galvanized coil production enterprises will continue to explore and innovate, and further improve product quality and production efficiency to meet the growing demand of the market.