About 1050 Aluminum

1050 aluminum is often used as metal for chemical equipment and thin plate processing parts. 1050 aluminum alloy 2000 series aluminum plate represents 2A16 (LY16) 2A06 (LY6) 2000 series aluminum plate is characterized by high hardness, among which copper metal content is the highest, about 3-5%. The 2000 series and 7000 aluminum sheets belong to aviation aluminum and are not commonly used in conventional industries. There are fewer manufacturers of 2000 series aluminum sheets in my country. The quality can not be compared with foreign countries. Imported aluminum sheets are mainly provided by South Korean and German manufacturers. With the development of my country's aerospace industry, the production technology of 2000 series aluminum plates will be further improved.

Basic information of 1050 aluminum

Material name: aluminum alloy

Grade: 1050

Standard: GB/T3190-1996

The characteristics and application of 1050 aluminum

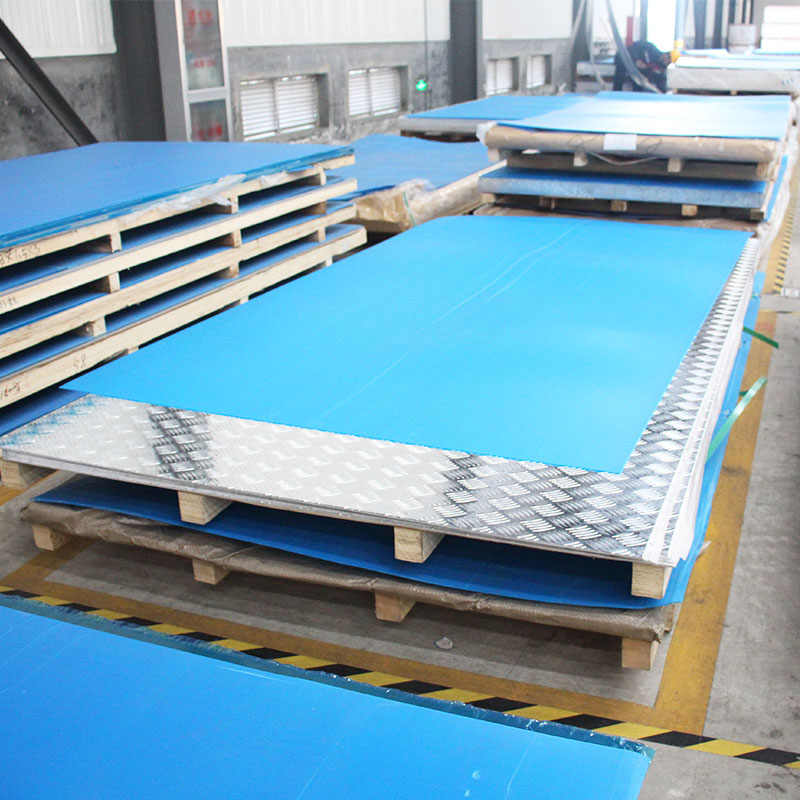

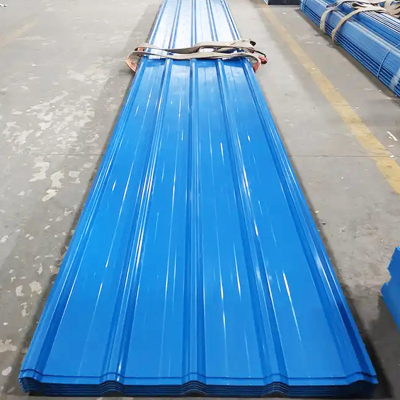

1050 aluminum alloy is formed by adding a small amount of copper element to pure aluminum, which has excellent forming and processing characteristics, high corrosion resistance, good weldability and electrical conductivity. Widely used in products that do not require high strength, such as chemical instruments, thin plate processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surfaces and disks, nameplates, kitchen utensils, decorations, reflective appliances, etc.

Chemical Composition of 1050 Aluminum

Aluminum Al 99.50,

Silicon Si≤0.25,

Copper Cu≤0.05,

Magnesium Mg≤0.05,

Zinc Zn≤0.05,

Manganese Mn≤0.05

Titanium Ti≤0.03, V

anadium V≤0.05, Iron

Fe 0.000~0.400