1100 Aluminum Coil

Product Name :1100 Aluminum Coil

Thickness :0.014mm-20mm

Width :60mm-2650mm

Coil Inside Diameter: 500 ~ 1,550 mm

Size:914mm,1000mm,1200mm,1219mm,1250mm,1500mm)

Weight: 3-8 tons per coil or as request

Type: Strip, Coil

Low Maintenance

High Performance

Affordable Excellence

Swift Delivery

Professional After-Sales Support

Product Description:

In automation equipment, such as the shell of the robot, the panel of the industrial automation control cabinet, etc., the application of 3003 aluminum alloy coil can improve the beauty and durability of the equipment, while reducing the overall weight of the equipment, and facilitate the installation and movement of the equipment.

Specifications of Aluminum Coil

Products Name | Aluminium Coil | ||

Alloy/Grade | 1050, 1060, 1070, 1100, 1200, 2024, 3003, 3104, 3105, 3005, 5052, 5754, 5083, 5251, 6061, 6063, 6082, 7075, 8011, 8079, 8021 | ||

Temper | F, O, H | MOQ | 5T for customized, 2T for stock |

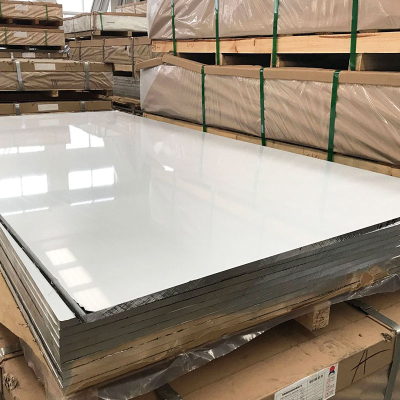

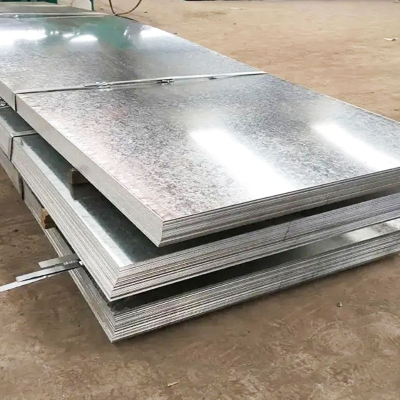

Thickness | 0.014mm-20mm | Packaging | Wooden Pallet for Strip & Coil |

Width | 60mm-2650mm | Delivery | 15-25days for production |

Material | CC & DC route | ID | 76/89/152/300/405/508/790/800mm |

Type | Strip, Coil | Origin | China |

Standard | GB/T, ASTM, EN | Loading Port | Any port of China, Shanghai & Ningbo & Qingdao |

Surface | Mill Finish, Anodized, Color coated PE Film Available | Delivery Methods | By sea: Any port in China |

Aluminum Alloy Grade of Aluminum Coil

Alloy Series | Typical Alloy | Introduction |

1000 Series | 1050 1060 1070 1100 | Industrial Pure Aluminum. Of all series, the 1000 series belongs to the series with the largest aluminum content. The purity can reach over 99.00%. |

2000 Series | 2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17 | Aluminum-copper Alloys. 2000 series is characterized by high hardness, in which the content of copper is the highest, about 3-5%. |

3000 Series | 3A21, 3003, 3103, 3004, 3005, 3105 | Aluminum-manganese Alloys. 3000 series aluminum sheet is mainly composed of manganese. The manganese content ranges from 1.0% to 1.5%. It is a series with a better rust-proof function. |

4000 Series | 4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A | Al-Si Alloys. Usually, the silicon content is between 4.5 and 6.0%. It belongs to building materials, mechanical parts, forging materials, welding materials, low melting points, and good corrosion resistance. |

5000 Series | 5052, 5083, 5754, 5005, 5086,5182 | Al-Mg Alloys. 5000 series aluminum alloy belongs to the more commonly used alloy aluminum series, the main element is magnesium, and the magnesium content is between 3-5%. The main characteristics are low density, high tensile strength, and high elongation. |

6000 Series | 6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02 | Aluminum Magnesium Silicon Alloys. The representative 6061 mainly contains magnesium and silicon, so it concentrates on the advantages of the 4000 series and 5000 Series. 6061 is a cold-treated aluminum forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance. |

7000 Series | 7075, 7A04, 7A09, 7A52, 7A05 | Aluminum, Zinc, Magnesium, and Copper Alloys. The representative 7075 mainly contains zinc. It is a heat-treatable alloy, belongs to super-hard aluminum alloy, and has good wear resistance. 7075 aluminum plate is stress-relieved and will not deform or warp after processing. |

Features of Aluminum Coil

1. Good temperature resistance

The melting point of aluminum is 660 degrees, and the general temperature does not reach its melting point.

2. Excellent Corrosion resistance

Because of its tight surface oxide film, it has strong adhesion, oxidation resistance, acid resistance, alkali resistance, corrosion resistance, decay resistance, and UV resistance.

3. Color uniform, long-lasting, even, and delicate

Soft and colorful, avoiding the individual chromatic aberration of traditional spraying, no matter how large the ceiling, its color, and color are consistent, lasting, and new.

4. Rigid joint, extremely high strength of the board

Rigid and tough combination, free to cut, slit, arc, balance, drilling, joint fixation, and edge compression molding.

5. Environmental protection

Not easy to turn yellow, using chromium-free treatment liquid to make up for the defects of easy discoloration of the laminating board; the roller paint contains active chemical molecules, which promote the formation of a protective layer on the surface of the material. Active chemical molecules are stable and easy to recycle, meeting environmental requirements.

Production And Shipping: